In today’s increasingly complex world of connected devices, the way we develop embedded software development and Human-Machine Interfaces (HMIs) is rapidly evolving. Device makers are shifting from simple MCU-based products to more sophisticated MPU-powered systems. This shift brings powerful capabilities — connectivity, advanced user interfaces, and cloud integration — but also new challenges. The biggest one? Collaboration.

At Witekio, we’ve seen firsthand that successful product development requires deep alignment between hardware and software teams, designers and developers, and across both front-end and back-end domains. Without this alignment, projects risk missing deadlines, overshooting budgets, or failing to deliver the features customers expect.

Here’s why hardware-software collaboration is essential for HMI development and how to do it right.Like this subject?

Check out our webinar: HMI Development & Agility | Witekio Webinar with QT

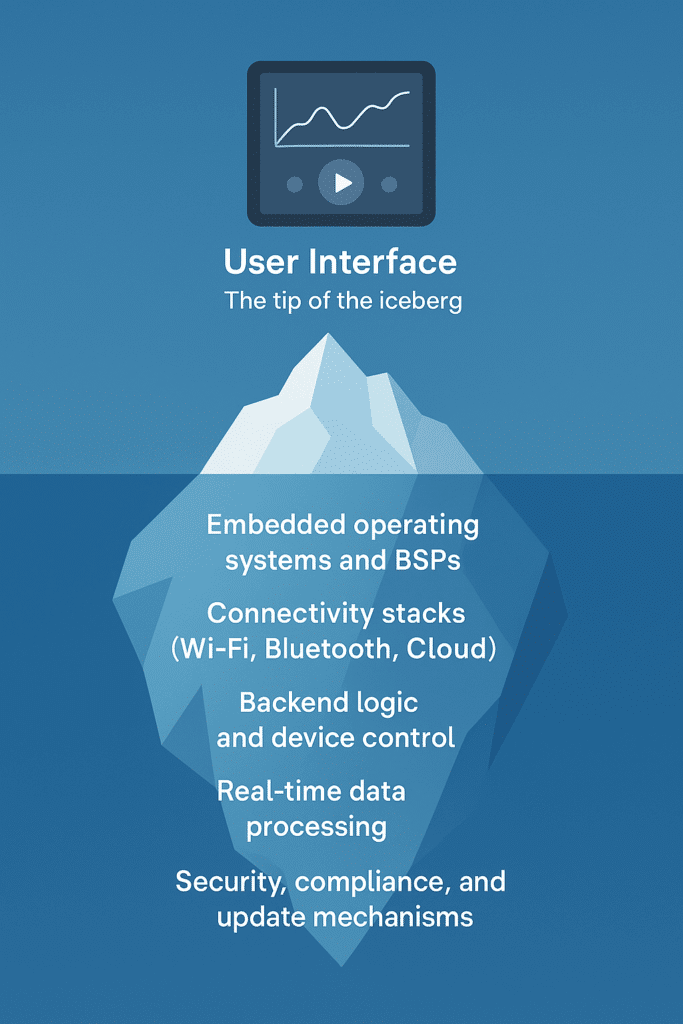

The Complexity Behind the HMI Screen

When people think of HMI development, they often imagine only the user interface: the touchscreen, the beautiful graphics, the animations. But in reality, the UI is just the tip of the iceberg.

Behind every interactive screen lies:

- Embedded operating systems and BSPs

- Connectivity stacks (Wi-Fi, Bluetooth, Cloud)

- Backend logic and device control systems

- Real-time data processing

- Security, compliance, and update mechanisms

All of these components need to work together seamlessly for a device to function reliably. And critically, they must evolve together throughout the product lifecycle — from design and development through industrialization, deployment, and long-term maintenance.

The mistake many device makers make is to separate these domains into silos: one team for hardware, one for back-end, one for front-end. But hardware-software integration is where complexity explodes — and where collaboration becomes a strategic advantage for robust HMI solutions.

Agility Is a Must For HMI Software Development

To manage this complexity, Witekio relies on agile development models. But we don’t treat agility as a rigid methodology. Instead, we adapt agile practices depending on the project, the customer, and the product maturity.

For example:

- Scrum by-the-book works for mature organizations who already apply agile internally.

- Exploratory Agile fits innovation and R&D projects where requirements evolve as features are discovered.

- Lean or Kanban models support smaller teams where full agile ceremonies may not be necessary.

- Disciplined Agile (Witekio’s “Maestro” approach) helps reconcile regulatory gates, hardware manufacturing timelines, and strict time-to-market constraints, while keeping iterative flexibility.

The goal is always the same: ensure constant prioritization, manage risks early, and give both Witekio and our customers the flexibility to respond to change — without losing sight of deadlines or budgets. This is the foundation of successful HMI software development.

HMI Developers and Designers must Speak the Same Programming Language

One of the most common friction points in complex product development is the handoff between HMI design and engineering teams.

Traditionally, designers work in tools like Figma or Photoshop and hand over static assets. Developers then translate these into code — a process that often introduces gaps, mismatches, and time-consuming back-and-forth.

A better approach is real-time collaboration, where both sides work in compatible environments from the start. This often means adopting frameworks and workflows that allow parallel HMI application development and shared standards, minimizing translation layers.

At Witekio, we support this collaboration in practice using tools like:

- Qt/QML and Slint, which allow designers to build and tweak UIs while backend developers work in parallel using clearly defined APIs.

- Flutter, when targeting embedded Linux or Android-based platforms, thanks to its cross-functional capabilities for front-end and back-end integration.

- Custom MVP architecture with mock APIs, enabling teams to test UI responsiveness and layout early, even before full backend functionality is implemented.

This approach helps teams:

- Share and reuse assets across disciplines

- Prototype directly on embedded hardware

- Define and enforce API contracts between frontend and backend early

- Use mock data to validate UX and backend assumptions without blocking progress

While front-end and back-end timelines don’t always align — especially when waiting on low-level features or hardware availability — Witekio often creates mock interfaces and simulation layers to allow parallel HMI programming and testing where possible.

We’ve applied this methodology in various industries, including medical, industrial, and consumer electronics, to help customers accelerate HMI development while the embedded stack and hardware catch up. This collaborative and iterative model improves integration quality and reduces the risk of surprises late in the product cycle.

Don’t Underestimate HMI Integration

As HMIs get richer, backend complexity grows exponentially. In many projects Witekio supports, two-thirds of total development effort happens on the backend side.

Backend teams must handle:

- Communication with hardware peripherals

- Motor and actuator control

- Cloud synchronization

- Security management

- OTA updates and device lifecycle management

The user experience may live on the touchscreen, but product success depends on robust backend HMI integration. That’s why collaboration between front-end and back-end engineers is so critical — and why both teams must understand each other’s constraints and timelines.

Frameworks Help Build Consistency

One of the ways Witekio enables efficient collaboration across teams is by recommending robust, industrial-grade frameworks that structure HMI development from the start.

These frameworks:

- Provide well-documented and version-controlled APIs, which allow frontend and backend teams to develop in parallel — even when hardware or drivers are still under development.

- Enable consistent architecture across front-end and back-end

- Offer proven toolchains for design, development, and testing

- Help enforce best practices and security standards

- Simplify long-term maintenance for product lines

By separating interface from implementation — for example, by mocking API responses while backend development is underway — teams avoid costly bottlenecks and can keep UI and UX iterations moving forward. This is especially valuable in projects where hardware access is delayed or backend logic is complex.

By building on these frameworks, rather than scattered libraries or ad hoc tools, HMI development becomes faster, more scalable, and better aligned across disciplines.

Test Early, Test Often — And Automate

Agility without quality is dangerous. With every sprint delivering new iterations, automated testing becomes mandatory to maintain stability.

From the earliest stages, UI components, backend logic, and system-level interactions should be tested continuously. At Witekio, we integrate automated testing pipelines directly into our agile workflows, ensuring that:

- Each sprint delivers stable, functional builds

- Regression risks are minimized as features evolve

- Bugs are caught early — not late in industrialization

This enables our customers to move fast without sacrificing product quality or risking last-minute surprises before release.

Collaboration Is No Longer Optional for HMI Development

As embedded products evolve into full digital complex systems, the old separation between hardware and software, design and development, is no longer sustainable.

Success today depends on:

✅ Cross-functional teams working together early

✅ Shared frameworks and toolchains that minimize friction

✅ Agile processes tailored to real-world product constraints

✅ Continuous testing embedded in development cycles

✅ Deep HMI integration of back-end and front-end teams

At Witekio, our role is not just writing software and HMI code — it’s helping our customers organize their development processes for long-term success.

Because great products are not just great designs or HMI coding — they are the result of great collaboration.

FAQ: EVERYTHING YOU NEED TO KNOW ABOUT HMI DEVELOPMENT

What is HMI development and why is it important?

How does HMI programming differ from HMI coding?

What role do PLCs play in HMI development?

In practice, not every system explicitly calls this component a “PLC” but the logic remains the same. Many everyday devices – from coffee machines to multi-cookers – rely on a similar architecture: a powerful board dedicated to running the HMI and a lower-level board (the PLC) that reliably drives the machine’s actuators, such as the heating element in a multicooker. For developers, this means mastering the PLC’s communication protocol is essential to ensure smooth integration with the HMI.

What are the main benefits of custom HMI solutions?

- Optimized user experience thanks to intuitive HMI screens

- HMI integration with existing control systems and operating systems

- Flexibility for embedded HMI development and future scalability

- Enhanced compatibility with web-based HMI solutions and cloud connectivity

Which tools and software are used in HMI software development?

How does HMI integration impact long-term maintenance?

How do I choose the right framework for HMI development?

What is the difference between an HMI and a SCADA system?

A SCADA system (Supervisory Control and Data Acquisition), on the other hand, goes a step further. It is mainly used in large-scale industrial environments such as energy plants, water treatment facilities, or manufacturing sites. Unlike HMIs, which are limited to local supervision, SCADA connects multiple HMI and PLC, consolidates their data, and provides a global, centralized view. This allows operators not only to control dispersed processes in real time but also to perform long-term monitoring, reporting, and analysis.